Cleanliness Particle Analyzers

Critical components going into fluid or air circuitry, engine components and some trasmission assemblies are need to free from particle contamination arising from manufacturing and assembly process. Particle contamination beyond limit will invariably affect the performance of the component during it’s life cycle.

Conation Technologies, a pioneer in India for cleanliness test equipment manufacturing, offers range of Automatic Particle Analysis Systems. Systems are compliant to most of the international standards such as VDA19.1, ISO16232-2018, ISO 4406 & 4407, ASTM F312 etc

Applications

• Engine, Transmission, Braking components

• Fuel and hydraulic line components

• Electronic components

• Fluids – Fuel, oils, coolants etc

• Cleanliness Analysis as per VDA19.1, ISO16232-2018, ISO 4406 & 4407, ASTM F312

Features/Highlights

• Particle size measurement right from 1 micron

• With Nikon’s unparalleled optics, each particle is captured with high resolution and measured to the highest accuracy.

• Quick scanning and faster processing to deliver the report in short time

• High resolution German made camera

• High precision ultra compact motorized stage with XYZ automation; programmable

• State of the art, Unified and simplified user interface software; user friendly navigation

• Intelligent Metallic Particle separation

• Advanced Fiber Identification with Elongated Length feature

• Adaptability for range of filters/membranes such as cellulose, Nylon, PTFE etc;

• Options for 25 mm and 90 mm scanning also available

• Specially designed Database and Reporting software

Specifications

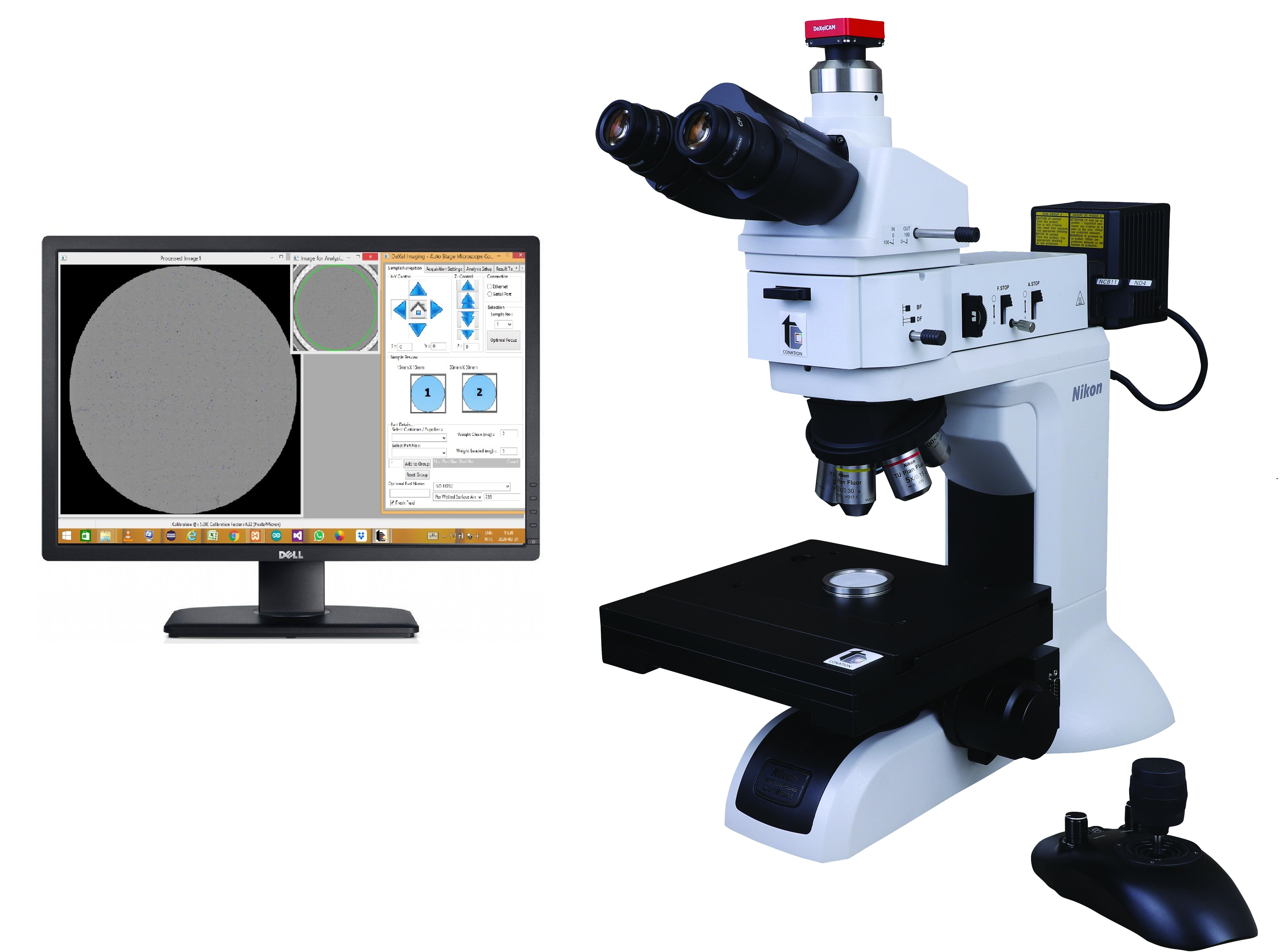

Nikon Microscope; Model: LV150N

• Modularized LV150 series Microscope with CFI60 Optical System

• CFI TU Plan FLUOR Epi 5X, 10X and 20X with high NA objectives

• Trinocular eyepiece tube ESD

• CFI 10X with diopter adjustment (F.O.V. 22mm)

• LED illumination with internal power source and intensity control, field diaphragm and aperture stop, can accept filters

• Sextuple Nosepiece

• Polarizer and Analyzer

• Expandable for Darkfield and DIC observation modes

World Class Nikon optics with Superior Optical performance and great resolution to visualize and capture crisp and clear images

Best in class with Higher NA

Highly corrected for chromatic aberration

Ultra compact Motorized stage with controller and Joystick

• High Precision screw and stepper motor driven XY stage

• Travel range - 80X60 mm

• Positioning accuracy - 10 micron

• Motorized Focusing (Z Drive) with adapter

• Controller for motorized X, Y and Z operation

• Joystick to operate motorized stage

• Specially designed sample holder for 47mm dia filter paper

High resolution camera, Made in Germany

• USB2.0, CMOS, Color

• 5 MP, High resolution

• 2.2X2.2 square pixel

• Rolling/Global shutter

Imaging Software

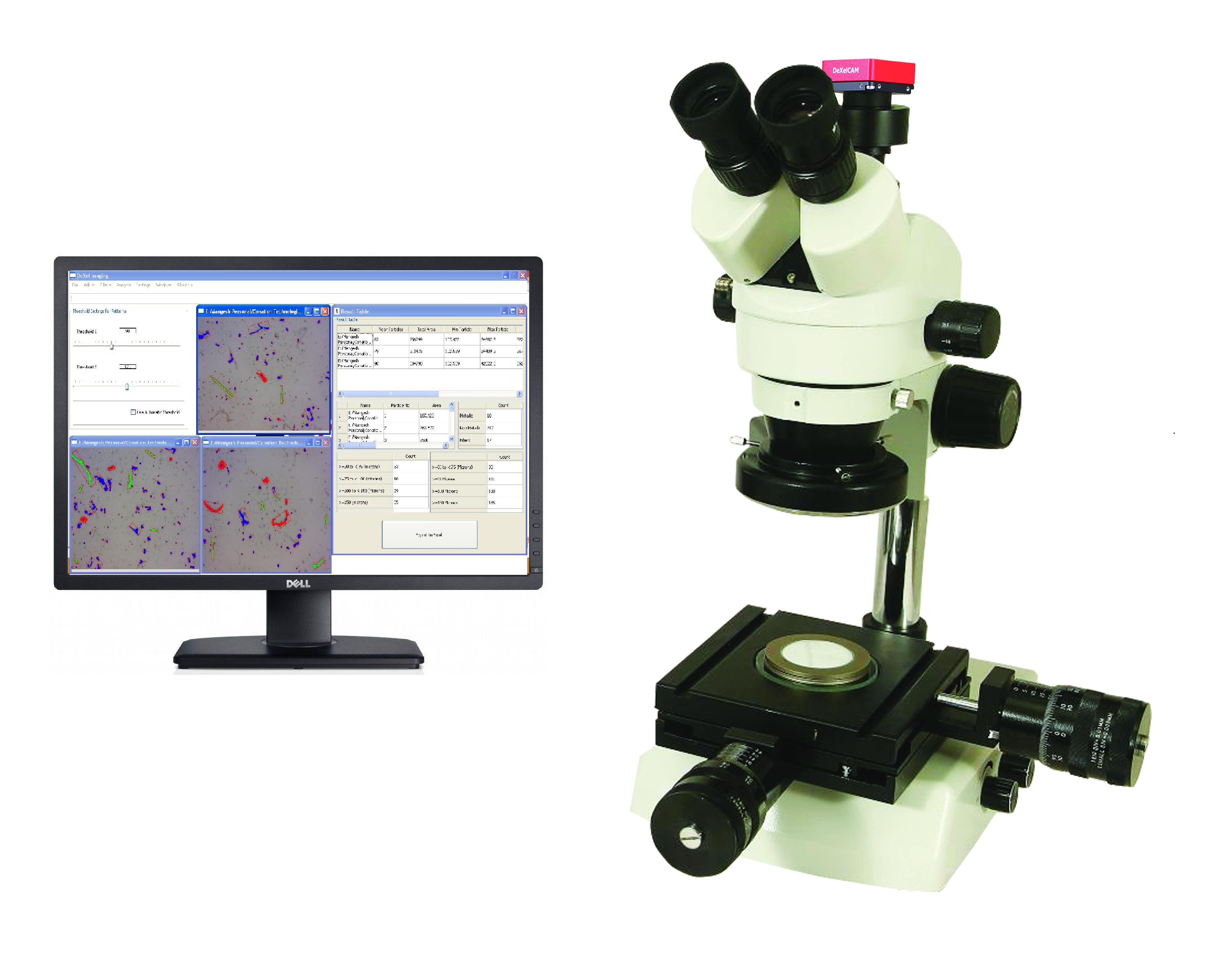

DeXel-Filtrate Imaging software

• Unified user interface software to harmonize the operation across all automatic models

• Specially designed Image analyzer to analyze and measure all particles on filter paper as per any applicable standard such as ISO16232-18, VDA19.1, ISO4406 etc

• Stitch all captured images to generate a single image of entire filter paper;

• Automatically analyze this single image for determination of particulate contamination as per desired standard

• Separation of particles as Metallic, Non-metallic, and fibres

• Distribution all particles into user/standard defined size classes

• Estimation of Filter Occupancy (Patch Saturation)

• Real time Auto-Focusing

• Intelligent Metallic Particle separation

• Advanced Fiber Identification with Elongated Length feature

Stage Operating Software

• XYZ movement control of stage from PC

Send

Message