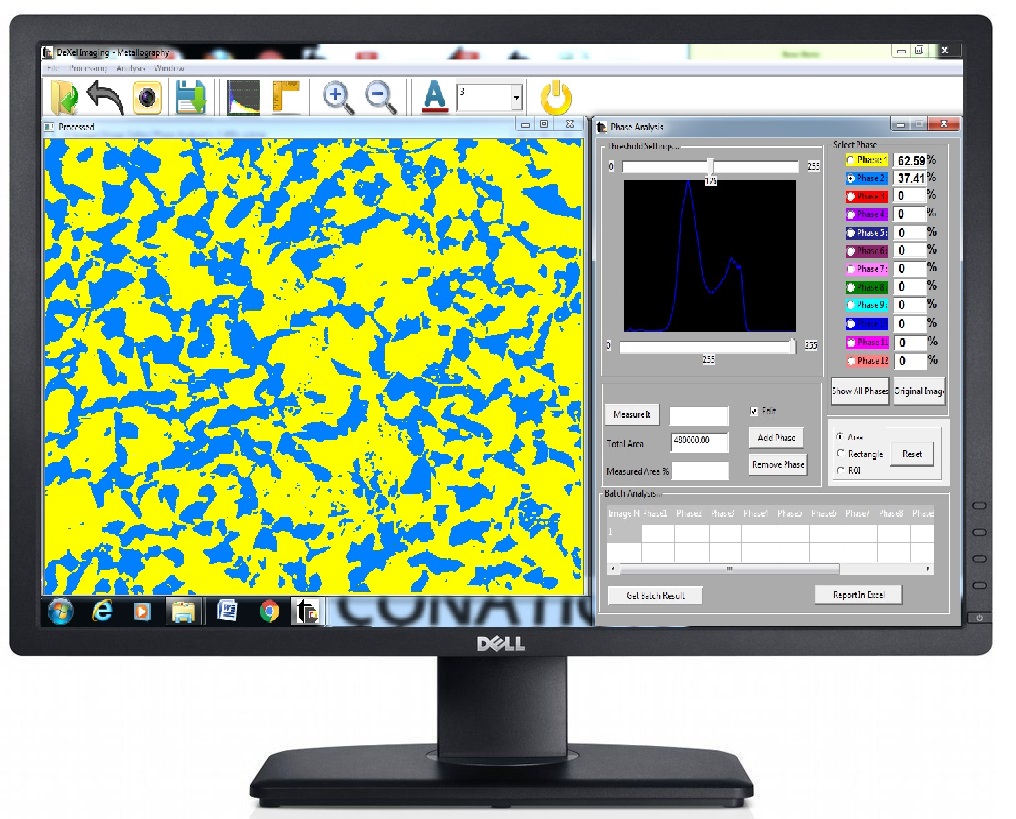

Qualification and quantification of microstructural features have always been crux of any metallurgical Analysis. Digitization of the microstructure with the help of image capturing hardware and storage into computer, analysis of these images with specialized image processing & analysis software modules has changed the complete scenario in material characterization. Tremendous advancements in computer technology and software developments has shifted manual interpretation methods to computerized ones in metallography, just like any other field. Image analyzers (comprehensive term which include image capturing, processing, analysis and reporting) has given great advantage to metallurgists in their everyday activities as well as in their research. Fatigue-free and User-friendly Analysis of microstructure with specialized image analyzers relieves tediousness and fatigue associated with manual measurements. Analyzing hundreds of fields manually could create tremendous fatigue and force the errors during analysis which are completely avoided in analysis through Image analyzers. Fast Just like any other computerized application, analysis of microstructure can be done extremely fast with image analyzers which also increases the productivity. Precision and Accuracy Inherent nature of software coding which is implementation of mathematical formulae renders highest possible precision and accuracy in any of the microstructure analysis. Repeatability and Reproducibility Computer being a deterministic machine which will always yield same results when same program is run on the same input. This makes Image Analyzer give full repeatability and reproducibility. Data Preservation All the analyses done and reports generated can be stored in digital format in your computer and you can retrieve the same any time in future without any much hassle. Dependability Though Image analyzer cannot replace the metallurgist, however a well trained staff can perform highly dependable analysis and produce the reliable results. Compliance to standards Mathematical and non-mathematical inputs from various ASTM, JIS, DIN and other international standards are typically translated into programs while writing the software of Image analyzer. So eventually these software modules are compliant to these standards. Cost Efficient After the initial cost of investment is done, there is no running cost for Image analyzer. This makes their use extremely cost efficient in daily use. -------------------------------------------------------------------------------------------------------------------------------------------------- Applications -Raw Material -Steel Mills -Forgings -Ferrous and Non-ferrous Castings -Heat Treatment -Weld structures -Electronic components -Petrography -Cement and Clinker -Material science Key Features Application Specific Analysis Modules – Grain size measurement; Phase analysis; inclusion analysis; nodularity, nodule count and size classification; graphite flake type, count and size classification; Porosity measurement, Banding Analysis, Decarb and coating thickness and many more… 2D analysis – Modules for measurement of count and various geometric aspects of features such as length, width, area, parameter, angle etc

Send Message