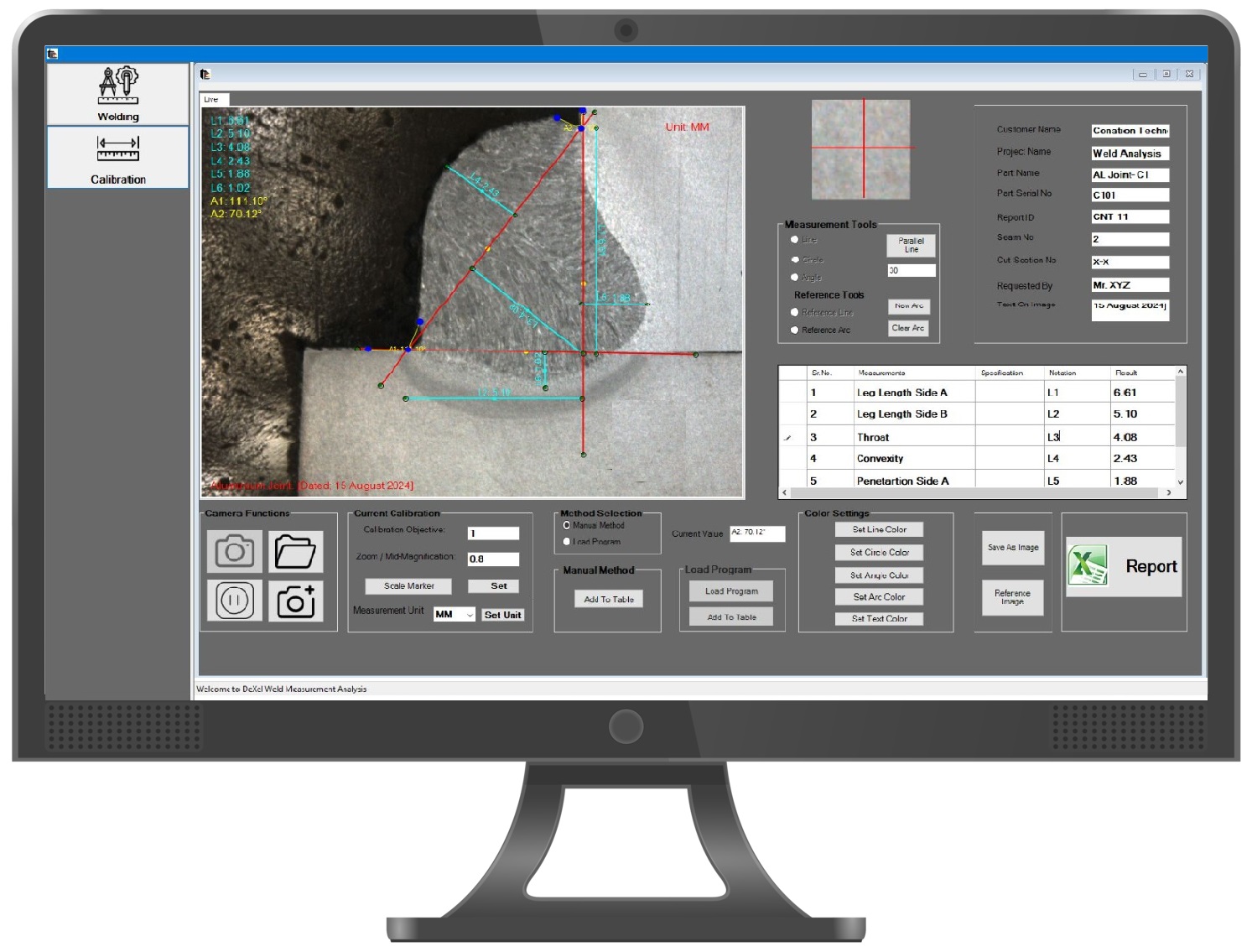

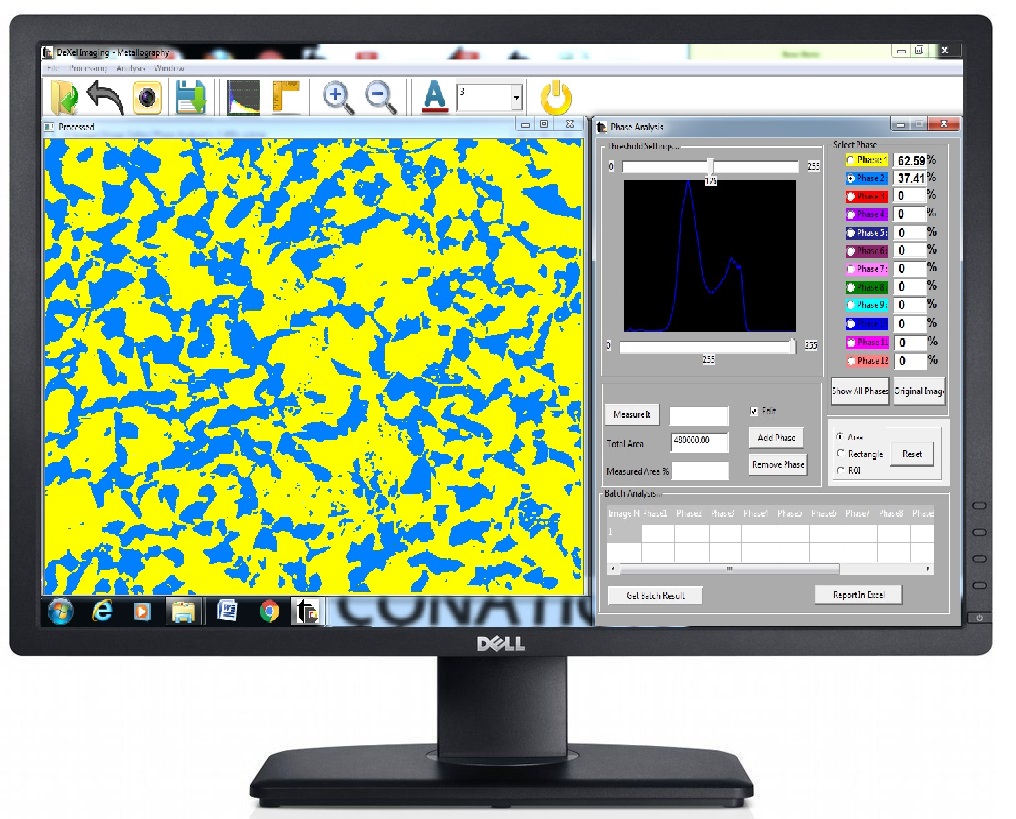

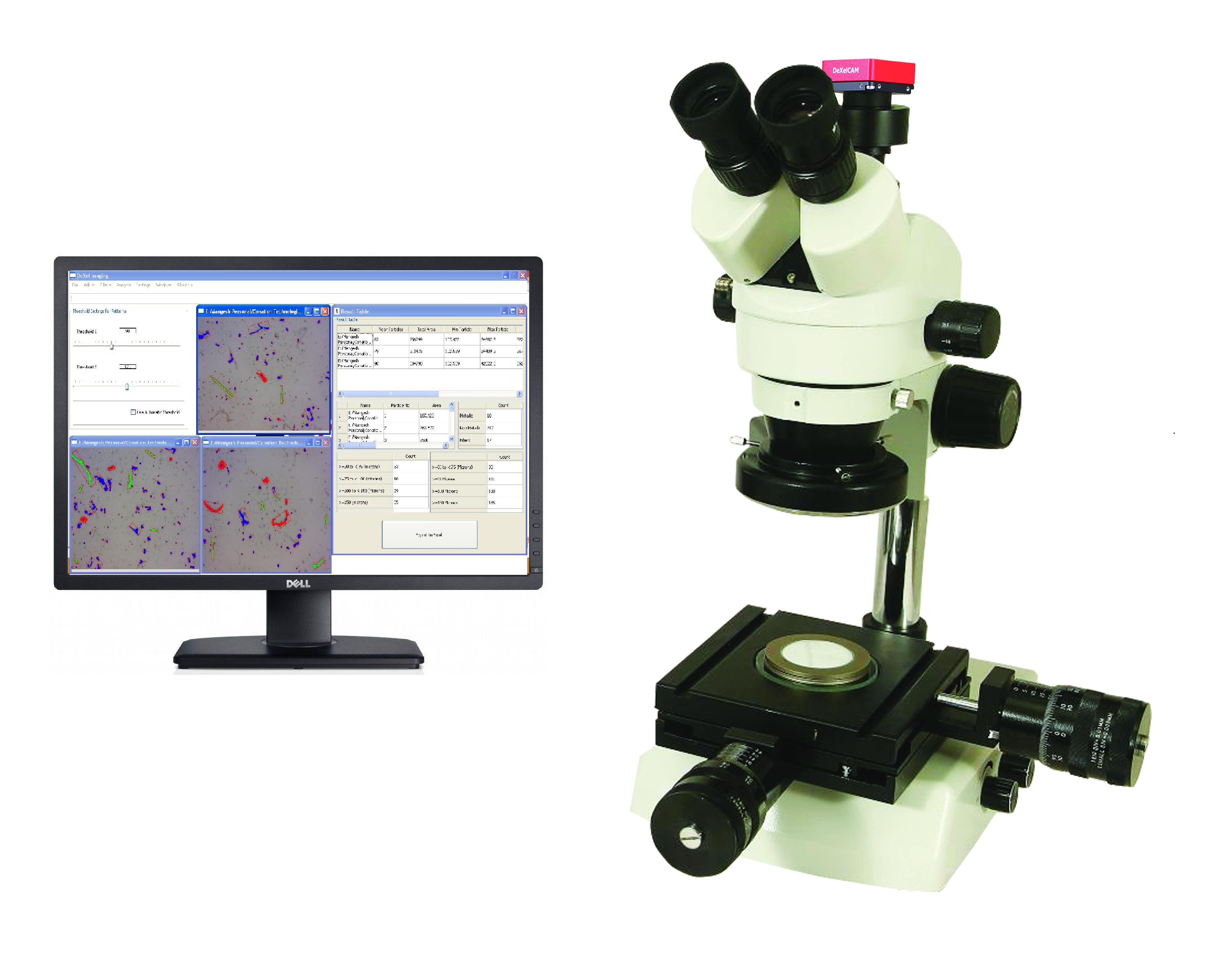

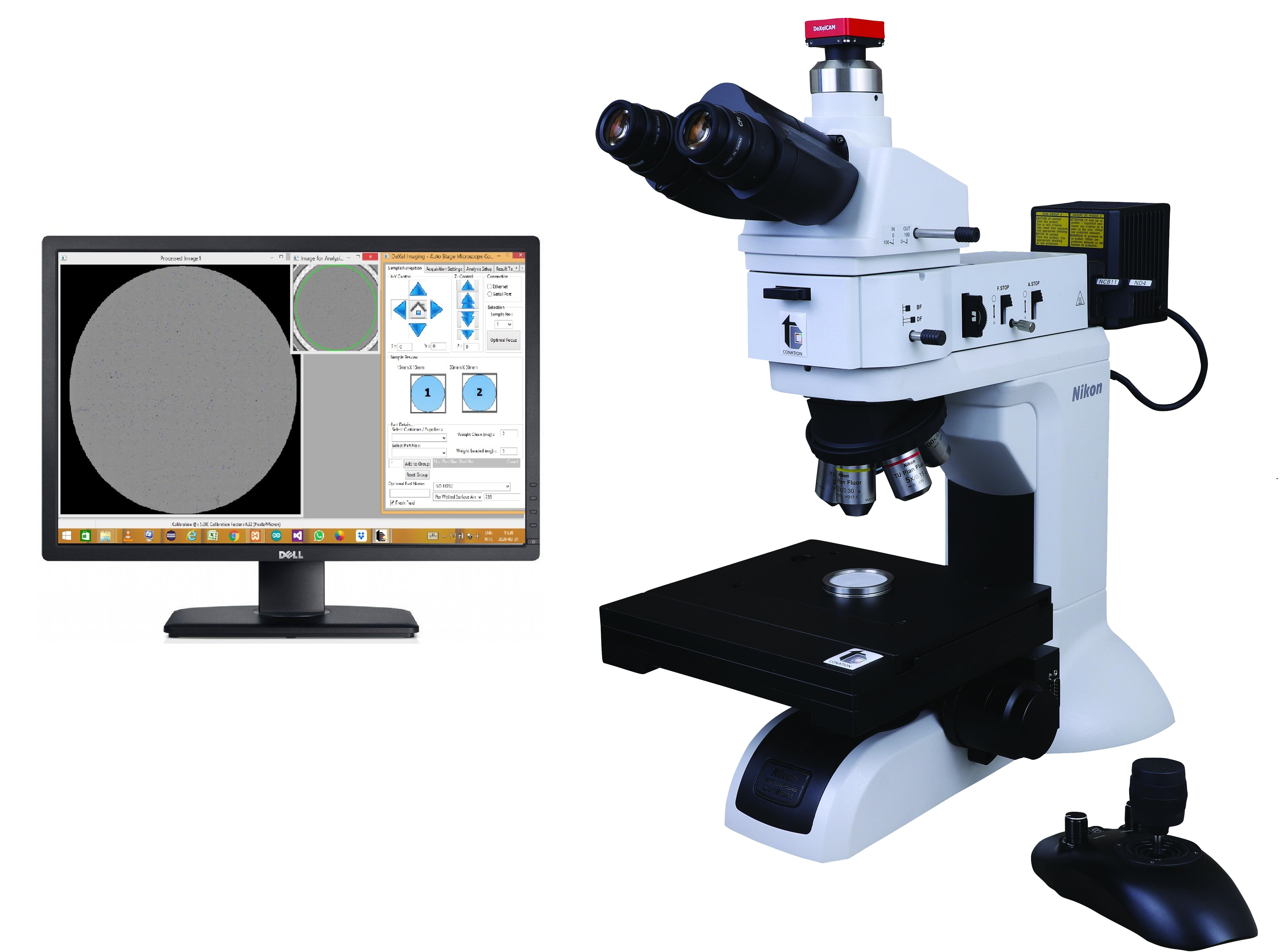

Weld structure analysis is extremely important to understand the quality of the weld, which in turn helps to understand the strength, performance and durability of the welded component. Any kind of weld such as butt weld, lap weld or T-joint weld should pass through the stringent macrographic inspection to reveal the intended quality, anomalies or disparities. Similar to metallography analysis, weld joint need to be cut in cross-sectional direction, polished to the mirror finish and etched with appropriate etchant to reveal the structure of bead, surrounding area, heat affected zone, weld passes etc. This sample then is placed under stereozoom microscope and further analysis can be carried out with DeXel-Weld Image analyzer. Weld Joint programs – Software has preloaded list with measurement parameters specific to type of weld joint like butt weld, lap weld, T-weld, corner weld, edge weld etc. Extensive list of parameters – List includes all the geometric parameters of weld such as Leg lengths, throat, penetrations, root penetration, metal thickness, gap, Area and depth of Heat Affected Zone, Joining Angles etc Macro based analysis - User can also preselect the parameters from the list and create a customized list depending upon specific requirements. The best part is that the macro can be created in user-friendly excel format. Color coded Measurements - All the measurements are color coded for better and quick understanding of the report. Porosity and other defect Analysis - Geometrical parameters such as length, width, area, perimeter estimation of defects such as porosity, crack, lack of fusion etc 2D analysis of features - Object counting, distance between any two points, angle between any two edges, Area of circle rectangle, irregular shape etc. OK/NOK Report – Limit values (Acceptance specifications) can be assigned to the each parameter and derived value can be compared which immediately confirms OK or Not OK reading. Report Generation – Simplified report in predefined excel template with facility to add logo, address etc.

Send Message